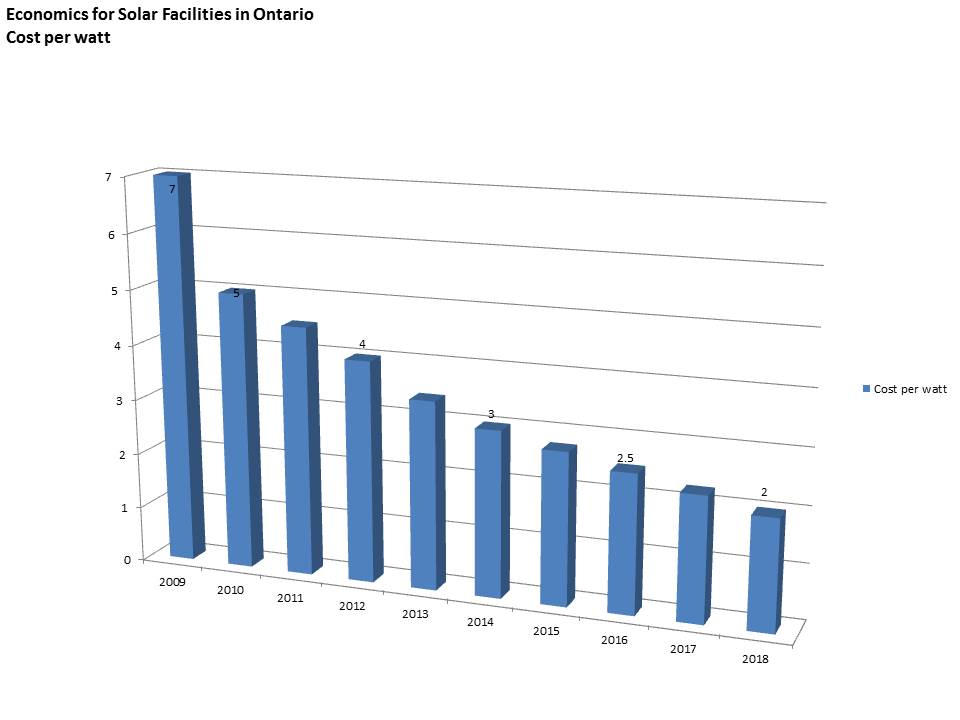

3. The nexus between the price of electricity and cost of solar (“Grid Parity”) is almost here, without any incentives. Grid parity occurs when an alternative energy source can generate power at a levelized cost of electricity (LCOE) that is less than or equal to the price of purchasing power from the electricity grid. The term is most commonly used when discussing renewable energy sources, notably solar power nd wind power. Grid parity depends upon whether you are calculating from the point of view of a utility or of a retail consumer. Reaching grid parity is considered to be the point at which an energy source becomes a contender for widespread development without subsidies or government support. It is widely believed that a wholesale shift in generation to these forms of energy will take place when they reach grid parity. Ontario is not at Grid Party for solar, yet, but its will be in the next couple of years. If you continue reading, #6 makes it a real possibility.

4. The Ontario government has mandated that electrical providers, Local Distribution Companies (“LDC”) allow their customers to offset their electricity use by generating renewable energy. This Ontario regulation has been around since 2005, its just now that a conversation can be had with regards to real economic benefits. Cost reduction or avoidance is the primary purpose of this program.

5. A lesser benefit from the financial aspect is the reputational boost. By using renewable energy to generate electricity without a contract, your firm will be seen by your investors, clients, employees and neighbours in a positive light. Other reasons include the following:

- Little to no global warming emissions,

- Improved public health and environmental quality,

- A vast and inexhaustible energy supply,

- Jobs and other economic benefits,

- Stable energy prices, and

- A more reliable and resilient energy system.

Lastly…..FREE MONEY!

6. The Canadian Manufacturer and Exporters Association (“CME”) has a Smart Green program (“SGP”) providing incentives at many steps through this process. There is up to $500,000 in incentive funds available for manufacturing facilities to bolster the return on investment (“ROI”).

So, what is the Solution? Answer: Solar Net Metering:

Net metering is a billing mechanism that pays solar energy system owners for the electricity they add to the grid. In its simplest form, a net metering customer will generate their own solar electricity during the day, use what it needs to meet the requirements of the home (or other type of building), injects the rest into the electricity grid, and consumes from the grid when the solar is unavailable. The customer is then only billed for their net electricity use. If they generate more than they use in a month, they receive a credit to apply against next month’s bill. If the solar system generates less than the customer uses, they will see a charge on their bill.

How to get started?

First off, find a consultant that has experience with the Canadian Manufacturers and Exporter (“CME”) Smart Green Program (“SPG”). This consultant should also be versed in Incentive Management and Solar consulting. This is where you get to apply for up to $500,000 in incentive money. You should be able to go through the entire process without any outlay of expense until you have to start building your solar facility. There are many “Off-ramps” to allow you to stop the process. Its very “risk-free” in its approach. That should help with moving forward.

This section is designed to outline each step in the process, so it is clear and concise. Where there is an incentive available, your consultant should apply for and secure the incentive before any work is started.

The following section will outline the entire process.

1. Incentive Management: Use an experienced incentive management consultant to manage all the facets of the Smart Green program. The upfront process will be to collect data on your operations and submit applications for funds at three different phases listed below. It should be noted that at each stage, the Client can choose to stop the process. The graphic to the right provides a visual of the process. As part of the intake process, the Client should be willing to provide:

- Detailed Company Information,

- Financial Information,

- Building Information,

- Utility Statements: 1-3 Years of Electricity and Gas bills,

- Corporate Signing officer information.

2. Incentive Application for Walk-through Assessment: Your consultant should facilitate applying for the incentive for this step with CME SGP process.

3. Walk-through Assessment: Once the incentive is approved, your consultant will conduct a walk-through assessment to determine the feasibility of installing a solar facility on your rooftop. This assessment cost will be reimbursed by the Smart Green program. The Walk-through will include:

- Introduction,

- Company Overview,

- Baseline GHG Emissions Overview,

- Walk-through Notes and Observations, and

- Potential SMART Green Project (Solar Project).

4. Incentive Application for Technical Assessment: Your consultant should facilitate applying for the incentive for this step with CME SGP process.

5. Technical Assessment: Once the incentive is approved, your consultant should conduct the technical assessment. This will provide you with the information to make your decision to move forward. If you hire a competent consultant that you trust, it should be straightforward. You should receive a technical assessment report containing the following items;

- Facility and Process Background,

- Facility Baseline GHG Emissions,

- Process Baseline GHG Emissions, if needed,

- Description of Energy Efficiency/GHG Reduction Measure (Solar Project),

- Expected Post-Project GHG Emissions,

- Capital Costs and Other Eligible Expenses,

- Additional Benefits, and

- Conclusion.

6. Incentive Application for Capital Funding for Project. Your consultant applies for the Capital Funding incentive for this step with CME SPG process. The detailed assessment will include:

- Introduction,

- Facility and Process Background,

- Facility Baseline GHG Emissions,

- Process Baseline GHG Emissions, if needed,

- Description of Energy Efficiency/GHG Reduction Measure (Solar Project),

- Expected Post-Project GHG Emissions,

- Capital Costs and Other Eligible Expenses,

- Additional Benefits, and

- Conclusion.

This is the point where you need to decide to spend money.

7. Engineer, Procurement Construction process: After the Capital Funding is approved, you should go to the market to find a vendor that can develop a comprehensive plan to implement the solar facility. This will include all the engineering design, electrical connections applications, equipment procurement, installation and commission of facility and provide ongoing operations and maintenance of the facility.